According to the Geothermal Exchange Organization, 'The earth is a huge energy storage device that absorbs 47% of the sun’s energy'… '500 times more energy than mankind needs every year-in the form of clean, renewable energy.' Geo-exchange systems use a portion of that energy as a heat source and heat sink for HVAC systems in buildings.

A common type of geo-exchange system is a ground-coupled, vertical bore system, in which a series of deep bores are drilled into the earth, a closed-piping loop is inserted into each bore, the bore hole is grouted with special thermally conductive grout, and the piping loop is interconnected to other closed vertical loops. Fluid is then pumped through the ground loops, using them as a heat exchanger, and then into the building, where the fluid is circulated through heat pumps. Other types of geo-exchange systems include horizontal ground heat exchangers, which use either straight or coiled (“slinky”) pipes buried in shallow trenches, and pond loops, where piping coils are submerged in a pond, and the pond becomes the heat source/sink.

Heat pumps are refrigeration equipment which serve as the “muscle” of the geo-exchange system, transferring heat from the geo-exchange fluid into the building in heating mode, and transferring heat from the building into the geo-exchange system in cooling mode. The amount of heat transferred by each heat pump typically ranges from three to six times the amount of energy consumed by the heat pump itself, making it very energy efficient.

In nearly all cases, the heat pumps used with geo-exchange systems are electrically driven, making them suitable for electrification (i.e. zero site carbon production). They are also compatible with renewable energy sources such as photovoltaic and wind generators.

In northern climates that require electrification in buildings for heating, a geo-exchange heat pump system is the most energy efficient HVAC system. Alternative heating system electrification choices include air source heat pumps, which use outdoor air as the building heat source/sink. However, in northern climates, these systems tend to suffer from a dramatic loss of efficiency when met with cold outdoor temperatures and direct electric heating elements.

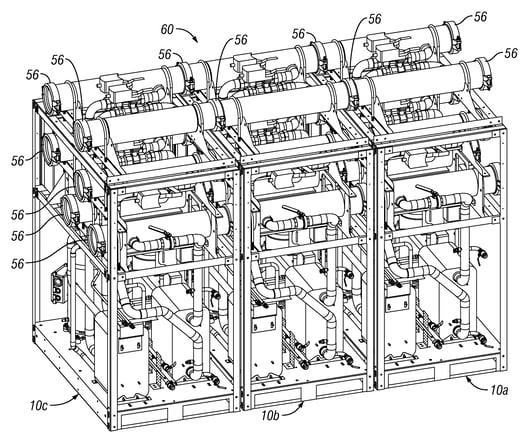

Heat pumps designed for use with geo-exchange systems are available as water-to-air units or water-to-water units. Water-to-air units include a fan, air filters, and a refrigeration system to transfer heat from the geo-exchange system fluid to the air passing through the unit. Water-to-water units, which use a refrigeration system to transfer heat between two fluid streams, can be used to generate heating hot water and chilled water for use in building heating and cooling systems. They can also be used to generate domestic hot water. While both water-to-air and water-to-water heat pumps use the geo-exchange system fluid as a heat source/sink, some water-to-water heat pumps can also be configured to allow the refrigeration system to directly transfer heat from the chilled water to the heating hot water, further reducing energy use.

Water-to-air heat pumps can be located in a ceiling space, in a closet, on the roof, or in a mechanical room. Water-to-water heat pumps are generally located in mechanical rooms. We also recommend locating heat pumps in mechanical rooms whenever feasible, since the refrigeration system on each heat pump generates noise and requires maintenance, with the air filters on water-to-air units requiring changing, and because water-to-air units create condensate (and the potential for condensate to leak) when in cooling mode.

The maximum water temperature produced by the commonly available water-to-water heat pumps on the market today is 125 degrees F to 130 degrees F. This limitation needs to be considered when designing new systems and can require significant system modifications if water-to-water heat pumps are to be applied to an existing hot water heating system that relies on higher temperature water. Some of the commonly available water-to-water heat pumps on the market today also allow the slow crossover of the load-side fluid (heating hot water and/or chilled water) with the source-side fluid. These units use the same fluid circuit within their internal heat exchanger for load-side fluid during one mode of operation after re-positioning some internal automatic valves, for source-side fluid during another mode of operation. Since the source-side fluid in a geo-exchange system typically contains an anti-freeze such as propylene glycol, the load side heating hot water and/or chilled water systems will need to anticipate the use of the same anti-freeze solution.

While geo-exchange heat pump systems are a logical system choice for zero-carbon buildings, with today’s natural gas and electric utility rates, they do not necessarily provide a solid economic choice as compared to high efficiency natural gas boilers in conjunction with high efficiency electric cooling systems. However, future utility pricing shifts and the possibility of carbon taxes are factors that could significantly favor geo-exchange systems.

Using a gas boiler during the coldest weather in a northern climate in conjunction with a geo-exchange system can provide several benefits: reducing the cost and footprint of the ground heat exchanger while still retaining most of its efficiency enhancement and carbon avoidance (near-zero instead of net-zero carbon); a backup heating system should a problem occur with the ground heat exchanger or its circulating pump, and fuel choice flexibility as fuel pricing continues to fluctuate.

If you would like more information on how any of these systems could be a benefit to you and your facilities, please contact us.

These Stories on MEP Engineering